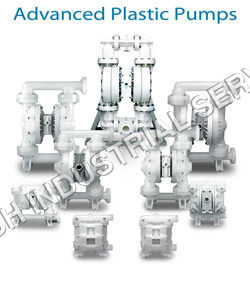

AODD Pumps

Product Details:

- Head Size 60 m

- Max Suction 7 m

- Mounting Type Flange / Feet Mounted

- Speed Variable

- Theory Reciprocating Pump

- Control System Manual / Solenoid Control

- Noise Level ≤ 70 dB

- Click to View more

X

AODD Pumps Product Specifications

- 8 Bar

- Corrosion Resistant, Dry Running Capable, Low Maintenance

- AODD (Air Operated Double Diaphragm)

- Air Driven

- Chemical Transfer, Wastewater, Food & Beverage

- 1” BSP / NPT

- Double Diaphragm

- -10°C to 80°C

- Self-priming

- 220V / 380V

- 25 mm

- Aluminium / SS316 / Polypropylene

- 50/60 Hz

- 8 Bar

- 50 LPM

- 7 m

- 60 m

- Variable

- Reciprocating Pump

- Dry / Wet

- Flange / Feet Mounted

- Industrial / Commercial

- Manual / Pneumatic

- Manual / Solenoid Control

- ≤ 70 dB

- PTFE / Viton

- 50 LPM

- ISO / CE

Product Description

Technical Data

- Material Availability : Aluminum,Ductilc Iron, Stainless,Steel Alloy C, Polypropylene, PVDF

- Size Availability : 6 mm (1/4'' to 76 mm (3'')

- Elastomer Temperature : Up to 177 °C (350°F)

- Elastomer option : Buna N .Neoprene, EPDM, Viton, Will. Flex '' Saniflex Polyurethane & PTFE

Performance Data

- Max. Flow : 1,021 lpm (270gpm)

- Max. Suction Lift : 9.8 m (32.0) wet, 7.6 m(25.0) dry

- Max. Solids size : 35 mm (1-3/8'')

Superior Versatility and Material Options

These AODD pumps allow users to select from Neoprene, Santoprene, Teflon, Viton, and Buna-N diaphragms, along with different body materials such as Aluminum, SS316, and Polypropylene. This flexibility ensures compatibility with a broad chemical spectrum and various applications in industry and commerce.

Operational Efficiency and Tool-Free Maintenance

Engineered for hassle-free maintenance, these pumps require minimal servicing and allow tool-free access to essential components. This reduces downtime, streamlines the maintenance process, and helps businesses maintain optimal operational flow with lower labor costs.

Wide Range of Applications and Performance

With a maximum flow rate of 50 LPM, a head size up to 60 meters, and a suction lift reaching 7 meters, these pumps are ideal for chemical transfer, wastewater management, and food and beverage industry uses. Their air-driven nature makes them suitable for hazardous or remote environments lacking electrical infrastructure.

FAQs of AODD Pumps:

Q: How do I choose the appropriate diaphragm material for my AODD pump application?

A: The diaphragm material should be selected based on chemical compatibility, temperature range, and process media. Neoprene and Buna-N are suitable for general-purpose duties, while Santoprene and Teflon are better for aggressive chemicals. Consult chemical compatibility charts or your supplier for precise recommendations based on your fluid.Q: What maintenance process is required for these AODD pumps, and when should it be performed?

A: AODD pumps are designed for minimal, tool-free maintenance. Routine inspection should be carried out every few months or as specified by operational hours. Components like diaphragms and check valves may require periodic checking or replacement, especially in demanding applications.Q: Where can these AODD pumps be installed, and are there specific mounting options?

A: These pumps can be installed in industrial and commercial settings, such as chemical plants, wastewater facilities, and food processing units. Mounting flexibility includes flange or feet-mounted orientations to match installation needs, in both horizontal and vertical port alignments.Q: What is the process for priming these AODD pumps before use?

A: No manual priming is necessary, as AODD pumps are self-priming. They are capable of dry or wet suction, and can lift liquid from depths up to 7 meters, making operation straightforward and reducing operational start-up time.Q: How does the air-driven operation benefit industrial users compared to electrically powered pumps?

A: Air-driven AODD pumps eliminate the risk of electrical sparks, making them safe for hazardous and explosive environments. They are also more adaptable to variable speed control, have fewer moving parts requiring lubrication, and can run dry without damage, offering operational safety and reliability.Q: What are the advantages of the corrosion-resistant and dry-running features in these pumps?

A: Corrosion-resistant construction protects against aggressive chemicals and ensures long-lasting performance, while dry-running capability allows the pump to operate safely even when the fluid supply is interruptedreducing the risk of damage and unplanned downtime.Other Products in 'Wilden Pumps ' category